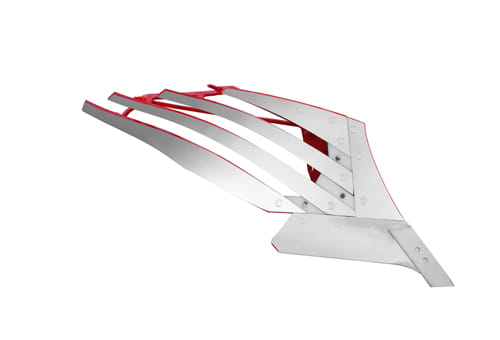

Kverneland 150 S Variomat

Леки до средно тежки почви, каменисти.

Трактори до 150 к.с.

Описание

Перфектното решение за висока ефективност

В леки до средно тежки каменисти почви

Регулиране на работната ширина "в движение"

Този навесен обръщателен плуг е предназначен за интензивна оран в малки до средни стопанства.

Новата конструкция на серия 150 дава възможност на фермера да намали своите оперативни разходи. Уникалната термична обработка, приложена върху целия плуг, гарантира характерните за Kverneland качества: отлични характеристики и дълъг експлоатационен живот дори при най-трудни почвени условия.

Лек, здрав, лесен за работа: технология на Kverneland!

Предимствата:

• Ниски изискания за повдигащия капацитет, лесно теглене, нисък разход на гориво

• Лесно регулиране на ширината на работните органи: Variomat

• Лесна настройка и експлоатация. Например, регулирането на водещия работен орган с помощта на системата на паралелограма води до автоматично коригиране на позицията на плуга

• Ненадмината система Auto-Reset на Kverneland за непрекъсната оран. Плужните тела се освобождават независимо едно от друго. Не е необходима поддръжка!

• Избор на напречен вал, категория II и III или вариант с механизъм за бързо свързване.

• Широка гама аксесоари

Kverneland Variomat:

• За оптимално съответствие между трактора, работните органи и почвените условия

• Повишава капацитета с над 40% (12-20”)

• Рентабилен: повишаване на производителността с 40 %, разходът на гориво на единица площ се намалява значително

• По-лесно се работи по права линия и близо до препятствия, напр. огради …

• Интелигентно регулиране на ширината на работните органи от седалката на трактора (предлага се и система за запаметяване на настройките)

• Саморегулираща се линия на теглене

Дълбочинно колело, монтирано към рамата или отзад според изискванията на фермера.

Предлагани размери:

6,00 x 9,00

200 x 14,5

320/60-12TT

500 x 165 (стомана)

Функционалности

Функционалности

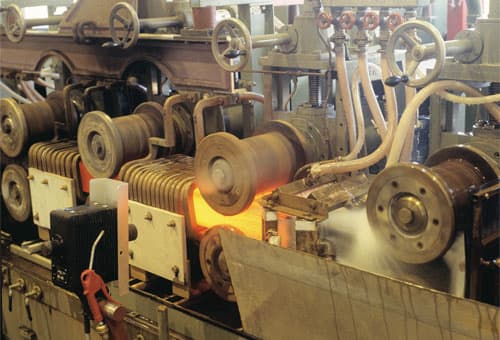

Значение на термичната обработка

- Рамата е съществена част на конструкцията на плуга. Съгласно стандартите за качество на Kverneland, всяка част, която не е термично обработена, е слаба част!

- Рамите на Kverneland са преминали през двойна индукционна термична обработка. Внимателно се следи преносът на топлина към стоманата. Якостта на рамата се увеличава 3 пъти. Уникалният индукционен процес на Kverneland осигурява здравина и гъвкавост, а обработените детайли се отличават с изключително дълъг експлоатационен живот.

По-здрава, но не и по-тежка

- За да постигнат здравината на Kverneland, конкурентите би трябвало да използват стоманена конструкция с по-големи размери или дебелина, т.е. рамата би била по-тежка.

- По-тежката рама изисква по-голяма теглителна сила, предизвиква по-голямо износване на частите, влияе отрицателно на повдигащия капацитет, експлоатационния живот на трактора и разхода на гориво.

Дълъг експлоатационен живот

- Заварките също са критично слабо място на рамата на плуга. Рамите на Kverneland се доставят като монолитна конструкция!

Предлагани рами

150 x 150mm рама с 3 работни органа, като може да се разшири с още 1 работен орган до получаване на 4-корпусен плуг или директно да бъде поръчан с 4 работни тела.

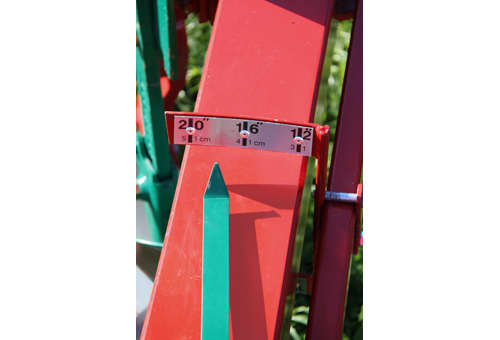

Система Vari-width® за безстъпково регулиране на работната ширина, от 30 до 50 cm (12 до 20”), в зависимост от модела. Патентованата в цял свят система на Kverneland се предлага във варианти с механично или хидравлично регулиране на ширината на работните органи.

Предимства:

•Лесна промяна на капацитета на плуга

•Перфектно съответствие във всеки момент между капацитета на трактора, работните органи и условията на почвата

•Пести време: до 30% по-голям капацитет

•Намаляване на разходите: до 18% по-малък разход на гориво при повишен капацитет на оран

•По-добри резултати от работата: оран в близост до плетове, огради, дървета и изкопи.

•Минимално износване: уникална неизносваща се шарнирна връзка между щангите и секцията на основната рама.

•Перфектна линия на теглене през цялото време. Системата Vari-width на Kverneland осигурява правилно паралелно позициониране на целия плуг. В резултат на това се улеснява тегленето и се намалява до минимум износването.

Отлично качество на оран

Плужните тела Kverneland са известни по цял свят с:

- Отлично качество на оран

- Изключителна износоустойчивост

- Ниски изисквания за теглителната сила

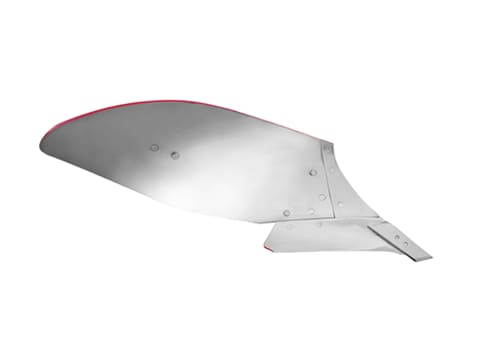

- Плужни тела от уникална стомана

- Уникална технология на Kverneland за обработка на метала: 12 часа термична обработка с цел насищане с въглерод

- Оптимална износоустойчивост (остри като диамант)

- Необходимата гъвкавост за поемане на удари

Тяло No. 8 – “Универсално тяло”

- За леки до тежки почви

- Добро заравяне на остатъците

- Лесно теглене

- Дълбочина: 15 до 30 cm (6 до 12”)

- Захват: 30 до 55 cm (12 до 22”)

Тяло No. 9 – “Дълбоко универсално тяло”

- За по-тежки почви и по-дълбока оран

- Добре обърнати и уплътнени бразди

- Лесно теглене

- Дълбочина: 15 до 35 cm (6 до 14”)

- Захват: 30 до 55 cm (12 до 22”)

Тяло No. 28 – “Тяло за широки гуми”

- Подходящо за всякакви почви; дори и за по-тежки почви от тяло No. 8

- Много широка бразда при гуми на трактора до 710 мм

- Добро обръщане и уплътняване

- Лесно теглене

- Подходящ за дълбочина: 15 до 30 cm ( 6 до 12”)

- Захват: 30 до 55 cm (12 до 22”)

Тяло No. 30 – “Лентово тяло”

- За лепкаво-каменисти почви и абразивни почви

- Добро представяне в по-тежки почви

- Най-добър разтрошаващ ефект

- Широко дъно на браздата,

- Дълбочина: 20 до 35 cm (8 до 14”)

- Захват: 30 до 55 cm (12 до 22”)

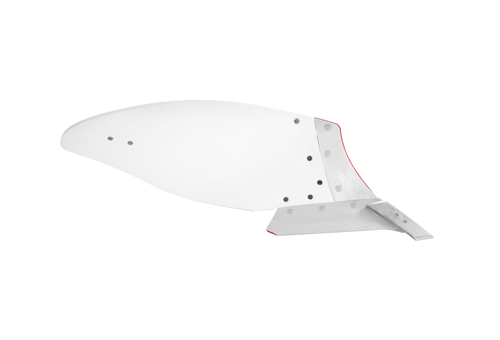

Тяло No. 34 – Пластмасова дъска

- Дълга и тънка форма (подобна на тяло 28)

- За почви с голямо съдържание на хумус, но без камъни

- Препоръчва се за трактори с големи гуми

- Лесно теглене

- Работна дълбочина: 12-35cm

- Захват: 30-55cm

- Почва / отметателна дъска: 40 градуса

Тяло No. 38

- Универсално тяло- Лесно за издърпване

- За всеки тип почвени условия

- Препоръчани за трактори с по-големи гуми

- От дълбока до плитка оран

- Перфектно обръщане в браздата

- Работна дълбочина: 12-35 cm

- Захват: 30-55 cm

- Почва/отметателна дъска: 40градуса

Без конкуренция при оран в каменисти почви!

Изцяло автоматичната система Auto-Reset на Kverneland, която не позволява прекъсване на работата, няма равна на себе си при оран в каменисти почви. Интелигентно проектираната система от многолистови ресьори позволява на краката на плуга да се освобождават плавно и ефективно над камъни и други твърди предмети. По този начин се избягват внезапни сътресения и евентуални повреди. След като плугът премине над препятствието, плужното тяло автоматично се връща в позиция за правилната дълбочина на оране.

Спазване на изискванията за безопасност

При съвременните изисквания за по-високи добиви, от тракторите и плуговете се очаква да работят по-бързо от всякога. Това повишава изискванията към оборудването, особено по отношение на системите за безопасност, създадени за да предпазват тракторите, плуговете и трактористите от щети, свързани с преминаването на плуга през скрити в земята препятствия. Системата Auto-Reset на Kverneland гарантира спазването на тези високи стандарти за безопасност.

Приспособими към различни условия на почвата

В зависимост от типа на почвите, всички плугове Kverneland може да бъдат оборудвани с различни пакети Auto-reset защита. При меки почви, например, обикновена 5-листов ресьор е най-добрият избор за перфектна оран при наличие на камъни. Днес почти всички плугове Kverneland се доставят с Heavy Duty (HD) 7-листов пакет. Той осигурява добро представяне в повечето случаи. Ако почвата е много твърда и камениста, препоръчително е да се използва пакет от 2 листа.

Допълнителни листа на Auto-reset защитата при необходимост

Стандартната Auto-Reset система включва 7 термично обработени листови пружини Kverneland (640Kp).

За по-трудни до екстремни условия на почвата се добавят допълнителни листови пружини до 1400kp.

Листовите пружини се закрепват лесно само с един централен болт.

Индивидуално освобождаване на тялото!

Механичната система Auto-Reset на Kverneland позволява на всяко плужно тяло да се освобождава независимо. По този начин се гарантира качеството на оранта.

Минимално износване и висока цена при препродажба

Системата Auto-Reset на Kverneland е доста проста конструкция, която в продължение на годините предпазва оборудването от нежеланите сили и се нуждае от минимална поддръжка. Спестявате Ви време и пари!

Освен това, системата Auto-Reset на Kverneland гарантира по-дълъг експлоатационен живот на плуга. При удар в препятствие се намаляват силите, приложени върху острието, рамата и компонентите на плуга. По този начин се намаляват механичните напрежения, на които са подложени плуговете Kverneland. Затова цената на препродажба на плуговете Kverneland е по-висока в сравнение с конкурентни продукти.

*ако се използва хидравлична система, налягането се повишава.

Технология на Kverneland за термична обработка:

- Над 130 години опит

- Стомани, които издържат и на най-трудните условия

- Най-добро съотношение здравина/тегло

- За постигане на същата здравина, други производители биха използвали повече стомана и съответно по-голямо тегло, а такова изделие би било с по-малка износоустойчивост и резултатите при оран ще са разочароващи

Стоманa от Kverneland:

- Предимства на по-малкото тегло:

по-лесно теглене / по-нисък разход на гориво / по-ниски изисквания за повдигащия капацитет / по-малко износване и натоварване на трактора / по-икономична работа - Предимства от по-добрата устойчивост :

минимални повреди / по-малка поддръжка / по-малка ротация на износващите се части / спестява време / най-висока стойност при препродажба на плуга / по-икономичен при работа - Проблемите винаги възникват тогава, когато използвате плуга и трябва да свършите работа в кратък срок!

С плуговете на Kverneland вие сте спокойни!

Повече информация: Kverneland Technology

Технически характеристики

Технически характеристики

Свалете каталог150 S Variomat |

|||

Брой работни органи |

3 |

4 |

5 |

Хедсток (макс. к.с.) |

150 |

150 |

150 |

Ø mm ос на хедсток |

110 |

110 |

110 |

Основна рама mm |

150x150 |

150x150 |

150x150 |

Просвет между работните органи |

85/100 |

85/100 |

85 |

Работна ширина |

12-20" |

12-20" |

12-20" |

Просвет под рамата cm |

70 or 75 |

70 or 75 |

70 or 75 |

Тегло кг |

1050 |

1275 |

1400 |

Защита |

Auto-Reset |

Auto-Reset |

Auto-reset |

Мин./макс. к.с. (препоръчителни) |

85/150 |

105/150 |

125/150 |